New method developed for identifying side products in LOHC systems

2 June 2025

Storing hydrogen in liquid organic carriers (LOHC) is promising because it allows for the safe storage and handling of hydrogen at low pressures. This makes LOHCs interesting for the future hydrogen economy because they can make transport and storage more efficient and safer.

Challenges in the long-term use of LOHC systems

An important aspect of all LOHC technologies is the long-term use of the carrier material in many repetitive storage cycles. However, this can lead to the formation of undesirable side products that remains on catalysts and impair their function, which makes reusing the systems difficult.

To better understand the formation of these side products, researchers at HI ERN and Friedrich-Alexander-Universität Erlangen-Nürnberg developed a new method.

Development of a Special Analysis Method

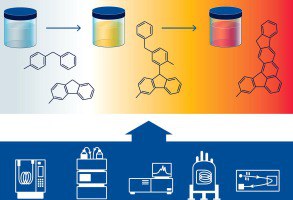

During the chemical conversion of the storage material — in this case, a substance called perhydro-benzyltoluene (H12-BT) — such side products can form. These side products are known as high-boiling compounds. The scientists developed a special analytical method to precisely identify these side products and determine their structures. In doing so, they identified coke precursor molecules in BT-based LOHC systems for the first time. These precursors dissolve from the catalyst in hot LOHC reaction mixtures. They are mainly formed by condensation and deep dehydrogenation reactions. The GC-FID method also allows for the accurate quantification of side products beyond methylfluorene.

A better understanding of these side products will allow for the optimization of processes in the future, minimizing contamination, reducing costs, and decreasing resource consumption—an important step towards a sustainable hydrogen economy.

The results of this collaborative effort were recently published in the journal "Fuel".

Hector Project: Large-Scale Plant for Hydrogen Storage

The publication was produced as part of the “Hector project”, which involves storing green hydrogen in LOHC on a ton scale at the Dormagen site.

The world's largest commercial plant for storing hydrogen in the liquid organic hydrogen carrier benzyltoluene has recently received official approval at Chempark Dormagen. With a capacity of around 1,800 tons of hydrogen per year stored in benzyltoluene, the plant aims to showcase the secure transportation and storage of hydrogen on an industrial scale. The plant is scheduled for completion and commercial operation by the end of 2027.

The “Hector” project also aims to provide scientific insights for further developing LOHC technology. HI ERN is providing scientific support for the project, focusing on optimizing the hydrogenation process and developing robust quality assurance processes for hydrogen and LOHC materials. HI ERN is also responsible for reprocessing LOHC materials for reuse in industrial applications.

The state of North Rhine-Westphalia is funding the project with nine million euros as part of the “progress.nrw” program, of which around two million euros have been awarded to the HI ERN for the scientific work.

Hydrogenious press release “Official approval granted for Hydrogenious LOHC’s ’Hector’ Storage Plant” (April 29, 2025)

Original Publication

Julian Henseler, Timo Schärfe, Julien Steffen, Andreas Görling, Michael Geißelbrecht, Peter Wasserscheid,

Detailed analysis of coke precursor formation in catalytic perhydro benzyltoluene dehydrogenation processes,

Fuel, Volume 398, 2025, 135500,

ISSN 0016-2361, https://doi.org/10.1016/j.fuel.2025.135500.